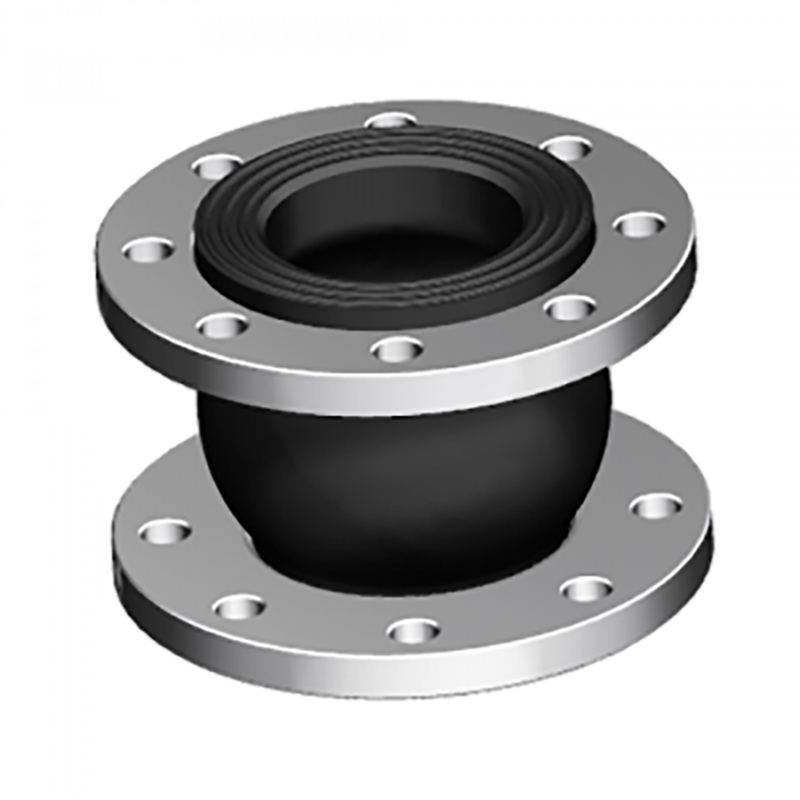

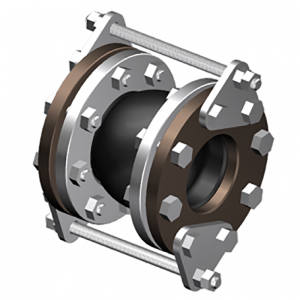

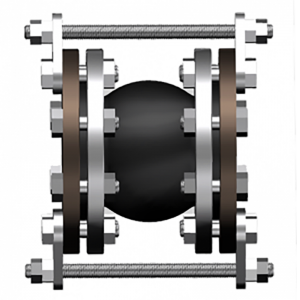

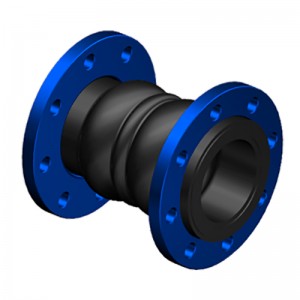

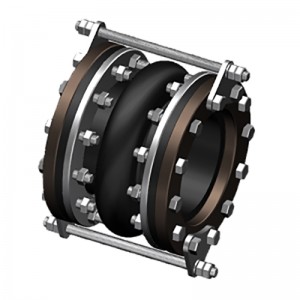

Wholesale Price China China Flanged Single Sphere Flexible Rubber Expansion Joint

Sticking to the belief of “Creating products of high quality and making friends with people from all over the world”, we always put the interest of customers in the first place for Wholesale Price China China Flanged Single Sphere Flexible Rubber Expansion Joint, We’ve been devoted to provide experienced purification technology and options for yourself!

Sticking to the belief of “Creating products of high quality and making friends with people from all over the world”, we always put the interest of customers in the first place for China Expansion Joint, Kst-F, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to supply the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

Details

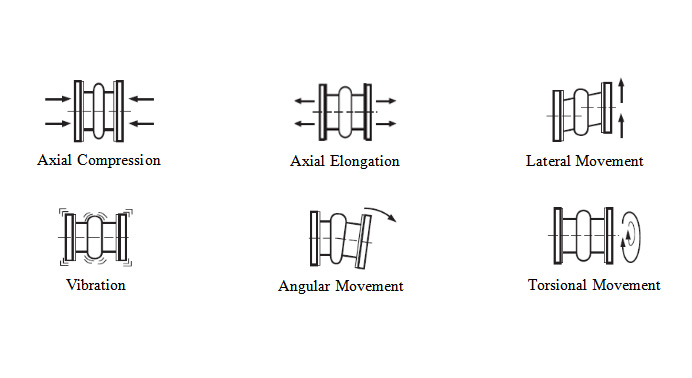

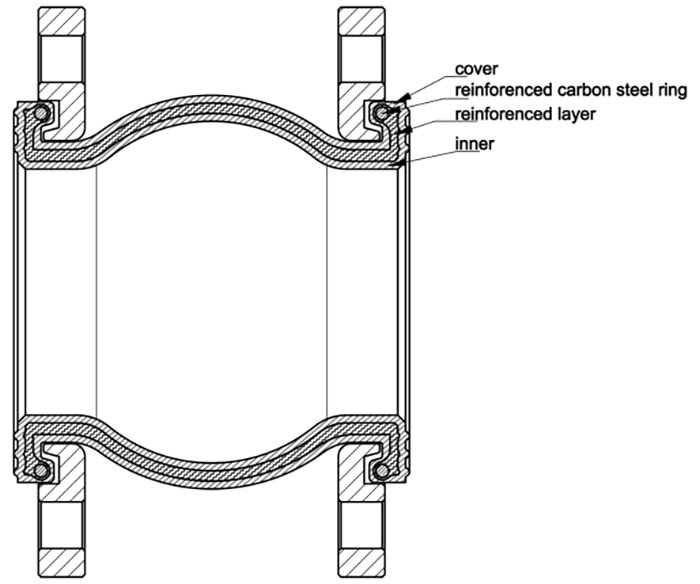

The single-arch product can reduce the vibration and noise, which can also solve the axial/lateral/angular movements/eccentric problems. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Single Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Standard O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

135 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

205 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

240 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

Single Arch-130MM |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

1 1/2″ |

40 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2″ |

50 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2 1/2″ |

65 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

3″ |

80 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

4″ |

100 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

5″ |

125 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

6″ |

150 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

8″ |

200 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

10″ |

250 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

12″ |

300 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

Single Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1″ |

25 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

37° |

225 |

26 |

|

1 1/4″ |

32 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

31° |

225 |

26 |

|

1 1/2″ |

40 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

27° |

225 |

26 |

|

2″ |

50 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

20° |

225 |

26 |

|

2 1/2″ |

65 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

17° |

225 |

26 |

|

3″ |

80 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

14° |

225 |

26 |

|

4″ |

100 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

14° |

225 |

26 |

|

5″ |

125 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

11° |

225 |

26 |

|

6″ |

150 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

9° |

225 |

26 |

|

8″ |

200 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

7° |

225 |

26 |

|

10″ |

250 |

8″ |

1″ |

5/8″ |

±3/4″ |

7° |

225 |

26 |

|

12″ |

300 |

8″ |

1″ |

5/8″ |

±3/4″ |

6° |

225 |

26 |

|

14″ |

350 |

8″ |

1″ |

5/8″ |

±3/4″ |

5° |

150 |

26 |

|

16″ |

400 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

18″ |

450 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

20″ |

500 |

8″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

24″ |

600 |

10″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

Single Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length(mm) |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1 1/4 |

32 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

1 1/2 |

40 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 |

50 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 1/2 |

65 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

3 |

80 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

4 |

100 |

150 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

5 |

125 |

175 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

6 |

150 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

8 |

200 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

10 |

250 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

12 |

300 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

Single Arch-Domestic Market |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

150 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

210 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

230 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

245 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang